Suggested Groove Design for Quattro SealsTM

Due to their unique four-lobed geometry, grooves for Quattro Seals are different than those for O-Rings. In general, Quattro Seal grooves are deeper, as less squeeze is required to affect a positive seal. Quattro Seal grooves are also narrower due to their ability to resist “spiral failure” better than O-Rings. The following chart displays general recommendations for Quattro Seal grooves.

| Seal No. | Cross-Section | Depth (dynamic) | Depth (static) | Width |

| 004 thru 050 | .070" ± .003" | .060"/.062" | .050"/.057" | .080" |

| 103 thru 170 | .103" ± .003" | .093"/.095" | .088"/.090" | .115" |

| 204 thru 276 | .139" ± .004" | .127"/.129" | .121"/.123" | .155" |

| 312 thru 382 | .210" ± .005" | .195"/.197" | .187"/.189" | .240" |

| 425 thru 464 | .275" ± .006" | .255"/.257" | .243"/.245" | .310" |

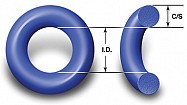

O-RINGS

The AS568 is the United States most popular O-Ring.

More

QUATTRO SEALS™

With twice the sealing surfaces compared to standard O-Rings, Quattro seals provide extra protection

More

TEFLON® ENCAPSULATED O-RINGS

These O-Rings are superior for gas permeation and aggressive chemical conditions.

More

BACK-UP RINGS

Backup rings help prevent O-Ring extrusion failure.

More