|

7108

S. Alton Way, Unit I |

(303) 758-2728

O-ring and Seal Design Theory

The use

of an o-ring as a seal is mainly to prevent the transfer of fluid

(liquid, solid or gas) between two or more regions. The components

of the seal are the o-ring itself and the contact surfaces. The elastomeric

o-ring relies on a compressive force acting on the o-ring to prevent

the transfer of fluid between regions. Successful seal design ensures

adequate seal compressive force while optimizing the destructive stress

acting on the o-ring as a result of the compression or of the environment.

The use

of an o-ring as a seal is mainly to prevent the transfer of fluid

(liquid, solid or gas) between two or more regions. The components

of the seal are the o-ring itself and the contact surfaces. The elastomeric

o-ring relies on a compressive force acting on the o-ring to prevent

the transfer of fluid between regions. Successful seal design ensures

adequate seal compressive force while optimizing the destructive stress

acting on the o-ring as a result of the compression or of the environment.

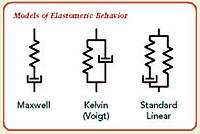

Three Models for Characterizing Viscoelastic Behavior Are:

- Maxwell Model (dashpot and spring in series)

- Kelvin (Voigt) Model (dashpot and spring in parallel)

- Standard Linear Solid (dashpot and spring in series with a spring in parallel).*

O-ring and Seal Design Topics

Incompressibility, Viscoelasticity and Thermomechanical Considerations

Nonlinear Finite Element Analysis (FEA)

Static Gland Dimensions - Axial-Static Glands

Static Gland Dimensions - Axial Vacuum - Static Glands

Static Gland Dimensions - Trapezoidal Vacuum

Static Gland Dimensions - Conical

Static Gland Dimensions - Tube Fitting Boss Seals

Static Gland Dimensions - Radial

Dynamic Gland Dimensions - Rotary Seals

Dynamic Gland Dimensions - Reciprocating Seals

Gland Design 1 - Special Considerations, Part 1

Gland 2 - Special Considerations, Part 2

Gland 3 - Special Considerations, Part 3

Elastomers for Semiconductor Plasma Environments

O-Rings and Seals in Vacuum Environments

* © Photographer: David Lemery of Milpitas, California, USA

We are located in the Denver Technological

Center in a suburb of Denver, Colorado

©1997-2017, Problem Solving Products, Inc.

Website Map | Privacy Statement

| Terms of Use