|

7108

S. Alton Way, Unit I |

(303) 758-2728

Home > Elastomer Properties > Tensile Stress

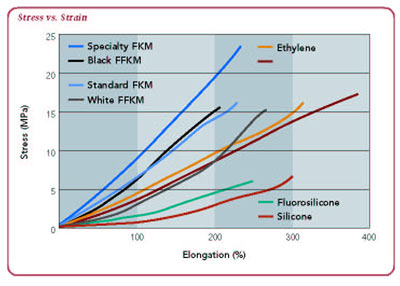

Elastomer Properties - Tensile Stress/Strain

Tensile strength is the maximum tensile stress reached in stretching a test piece (either an O-ring or dumbbell).

Elongation: The strain, or ultimate elongation, is the amount of stretch at the moment of break.

Modulus: Also called “Mod 100,” this is the stress required to produce a given elongation. In the case of “Mod 100,” the modulus would be the stress required to elongate the sample 100%. In elastomers, the stress is not linear with strain. Therefore the modulus is neither a ratio nor a constant slope—but rather denotes a point on the stress-strain curve.

Tensile tests are used for controlling product quality and for determining the effect of chemical or thermal exposure or an elastomer. In the latter case, it is the retention of these physical properties, rather than the absolute values of the tensile stress, elongation or modulus, that is significant.

Test Methods:

-

ISO 37

-

ASTM D412

Next topic Elastomer Properties - Bulk Modulus/Resiliency

We are located in the Denver Technological

Center in a suburb of Denver, Colorado

©1997-2017, Problem Solving Products, Inc.

Website Map | Privacy Statement

| Terms of Use