|

7108

S. Alton Way, Unit I |

(303) 758-2728

Home > Mechanical Seals Operating Principles > Fluid Leakage

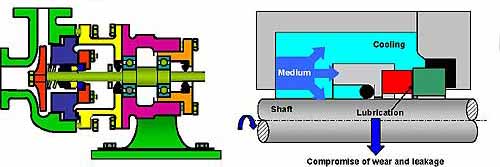

Mechanical Seals Operating Principles

The fluid in the pump and seal area

Key Point: the fluid contacts the seal faces and other parts in wide open areas, in very small gaps and at the exit of the seal faces. Pressure and temperature of the fluid will depend on its location and determine its respective state, i.e. liquid, gaseous, solid or a mixture.

A few facts about the leakage (and wear) behavior of contacting mechanical seals:

- It is essential for proper lubrication and wear of the faces.

- Normal leak rates range between immeasurably small to steady drips or temporary to even small steams. Some seals leak some of the time, some seals never leak (measurably), and some leak all the time. Leakage patterns can be constant, progressive or erratic in nature.

- It can be in liquid, gaseous and/or solid state.

- Successful contacting seals tend to have very low wear rates and low leakage rates.

- Some forms of contact is necessary for low leakage rates. Non-contacting or “full lift off” seals (hydrostatic or hydrodynamic tend to have visible, sizeably larger leakage rates.

- The large majority of mechanical seals never wear out and are removed from service for some other reason.

- Seal failures

occur for a wide range of reasons. Some failures occur as an

interaction with the tribology of the interface.

Next: Effective forces in a mechanical seal

We are located in the Denver Technological

Center in a suburb of Denver, Colorado

©1997-2017, Problem Solving Products, Inc.

Website Map | Privacy Statement

| Terms of Use