|

7108

S. Alton Way, Unit I |

(303) 758-2728

Home > O-ring, Seal Design > Finite Element Analysis

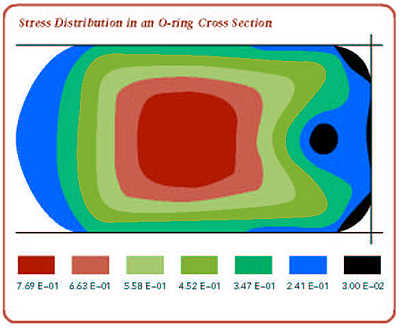

Nonlinear Finite Element Analysis (FEA)

Rubber

is a unique material. In its polymer form during processing, it behaves

like a highly viscous liquid. After cross-linking (curing), rubber can

undergo large reversible deformations. The unique properties of rubber

that require treatment different from traditional metal nonlinear finite

element analysis are:

Rubber

is a unique material. In its polymer form during processing, it behaves

like a highly viscous liquid. After cross-linking (curing), rubber can

undergo large reversible deformations. The unique properties of rubber

that require treatment different from traditional metal nonlinear finite

element analysis are:

- Large deformations (over 100%).

- Load-extension (stress-strain) characteristics are definitely nonlinear.

- Viscoelastic (spring and dampener) characteristics and timeand temperature-dependence.

- Nearly incompressible (volume does not change appreciably under stress).

The finite element method is a technique for obtaining approximate numerical solutions to boundary value problems which predict the response of physical systems when subjected to external loads. The system or structure is characterized by many small individual pieces or elements which are connected at nodes. The solution of thousands of simultaneous equations for unknowns of displacements, rotations, or the hydrostatic pressure is obtained through a computer.

Nonlinear finite element analysis should be an integral part of the design and manufacturing processes. The advantages are numerous, including improved performance, faster time-to-market, optimal use of materials and verification of integrity before prototyping.

Next Topic Static Seal Gland Design

*Nor-Cal Products, Permeation of Various O-Rings, 1998

We are located in the Denver Technological

Center in a suburb of Denver, Colorado

©1997-2017, Problem Solving Products, Inc.

Website Map | Privacy Statement

| Terms of Use